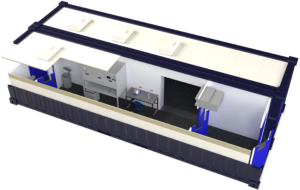

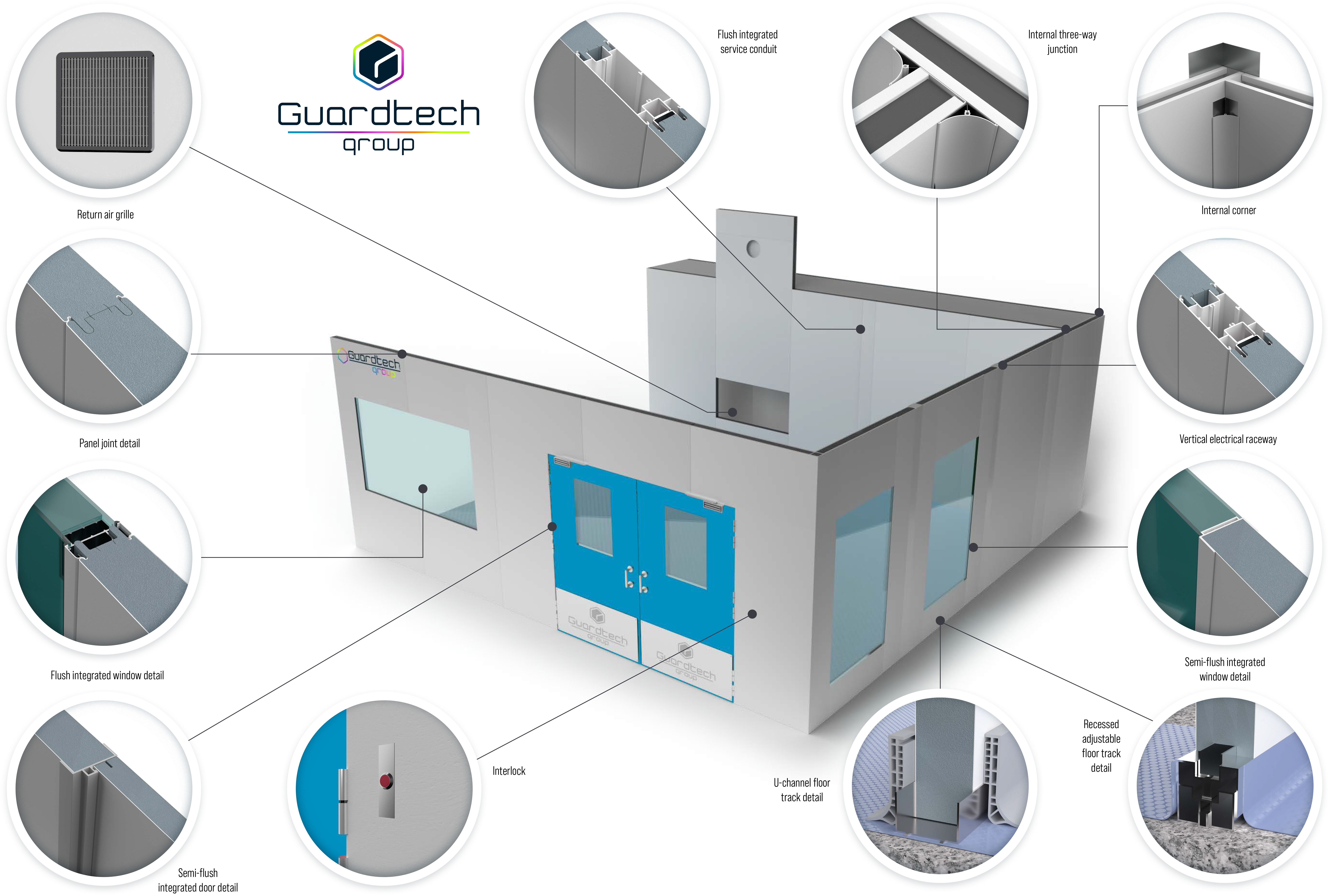

THE ISO Specification is the most appropriate combination of components to achieve an ISO 14644 classified environment.

Balancing a high-quality, clean finish with a cost competitive Specification enables CleanCube ISO to meet the full spectrum of ISO 5 to 8 classification whilst ensuring value for money and time to build remain the critical factors.

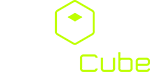

ISO utilises a composite panel system for the main structural elements, such as walls and ceilings, and ensures that interfacing components including doors, glazing, flooring, lighting, filtration, grilles and accessories are manufactured from high quality materials and intelligently incorporated into the installation.

The CleanCube ISO Specification also logically incorporates and conceals all utilities by taking advantage of the channel behind the wall panels – which also serves as a return air void. This feature reduces ledges and crevices to aid cleaning, support compliance and improve overall facility aesthetic.

ISO SPECIFICATION TECHNICAL DATA

Components

-

Classifications Available

ISO 5, 6, 7, 8 & BSL 3

Classifications Available

ISO 5, 6, 7, 8 & BSL 3

-

Walls: GT Shell Pro

60mm or 80mm thick Quadcore panels with a CLEANSafe coating that fit together intelligently via a unique de-ended solution, fitted into a base channel with integrated semi-flush doors and windows. An aluminium top hat profile is placed into the de-ended panel with the panel face folded around, de-ending to both the top and bottom of the panel. This unique detail allows for integration into an adjustable floor track. DOWNLOAD DATA SHEET

Walls: GT Shell Pro

60mm or 80mm thick Quadcore panels with a CLEANSafe coating that fit together intelligently via a unique de-ended solution, fitted into a base channel with integrated semi-flush doors and windows. An aluminium top hat profile is placed into the de-ended panel with the panel face folded around, de-ending to both the top and bottom of the panel. This unique detail allows for integration into an adjustable floor track. DOWNLOAD DATA SHEET

-

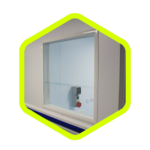

Doors: GT Access Pro

Featuring QuadCore technology which offers superior fire protection, thermal and environmental performance and a CLEANSafe coating, GT Access Pro semi flush hinged door leafs are constructed from two facings 0.63mm thick hot-dip zinc coated metal to EN 10147, folded to form a 40mm thick door leaf. The edges of the two skins are pressed to create a monobloc cassette construction with smooth folded edges. Each vision panel is constructed from two 6mm laminated safety glass panels – standard size 300 x 600mm. DOWNLOAD DATA SHEET

Doors: GT Access Pro

Featuring QuadCore technology which offers superior fire protection, thermal and environmental performance and a CLEANSafe coating, GT Access Pro semi flush hinged door leafs are constructed from two facings 0.63mm thick hot-dip zinc coated metal to EN 10147, folded to form a 40mm thick door leaf. The edges of the two skins are pressed to create a monobloc cassette construction with smooth folded edges. Each vision panel is constructed from two 6mm laminated safety glass panels – standard size 300 x 600mm. DOWNLOAD DATA SHEET

-

Glazing: GT Vision Pro

Designed as semi flush mounted glazed frame for the GT Shell Pro de-ended panel system. The glazing units consist of two aluminium frames (frame and counterframe) on which 6mm laminated glass is glued and siliconed on both sides. The aluminium frame is available in RAL 9002 or RAL 9010 colours as standard – the bottom of the frame is supplied with moisture-absorbing silica gel granules in order to keep the glazing unit cavity moisture-free.

Glazing: GT Vision Pro

Designed as semi flush mounted glazed frame for the GT Shell Pro de-ended panel system. The glazing units consist of two aluminium frames (frame and counterframe) on which 6mm laminated glass is glued and siliconed on both sides. The aluminium frame is available in RAL 9002 or RAL 9010 colours as standard – the bottom of the frame is supplied with moisture-absorbing silica gel granules in order to keep the glazing unit cavity moisture-free.

-

Ceiling: GT Lid Pro

A 45mm radius coving is applied to bridge the 90-degree join between wall and ceiling panel. Ceiling panels use the same ultra-airtight integrated envelope system, utilising extruded aluminium interface connection profiles to ensure a fully flush detail – finished with silicone seal. Pre-formed corner panels provide a flush finished external corner detail. DOWNLOAD DATA SHEET

Ceiling: GT Lid Pro

A 45mm radius coving is applied to bridge the 90-degree join between wall and ceiling panel. Ceiling panels use the same ultra-airtight integrated envelope system, utilising extruded aluminium interface connection profiles to ensure a fully flush detail – finished with silicone seal. Pre-formed corner panels provide a flush finished external corner detail. DOWNLOAD DATA SHEET

-

Flooring: GT Deck Plus

ESD vinyl, hot-welded and coved 100mm from floor level with a fully flush connection to wall via intelligent recessed floor track detail which vinyl lays under with silicone sealed finish. DOWNLOAD DATA SHEET

Flooring: GT Deck Plus

ESD vinyl, hot-welded and coved 100mm from floor level with a fully flush connection to wall via intelligent recessed floor track detail which vinyl lays under with silicone sealed finish. DOWNLOAD DATA SHEET

-

Utilities Integration

Most utilities will be terminated with wall mounted sockets/outlets with wiring, pipework and containment concealed behind the wall panel within the return air plenum. All penetrations will be silicone sealed, small power and data sockets will be flush mounted.

Utilities Integration

Most utilities will be terminated with wall mounted sockets/outlets with wiring, pipework and containment concealed behind the wall panel within the return air plenum. All penetrations will be silicone sealed, small power and data sockets will be flush mounted.

-

Lighting: GT Lux Plus

Recessed LED, 4k colour temperature, 4,400 lumens per light fitting providing 500 lux at bench level. Roomside access diffuser for clean LED change. PIR motion sensor activated. DOWNLOAD DATA SHEET

Lighting: GT Lux Plus

Recessed LED, 4k colour temperature, 4,400 lumens per light fitting providing 500 lux at bench level. Roomside access diffuser for clean LED change. PIR motion sensor activated. DOWNLOAD DATA SHEET

-

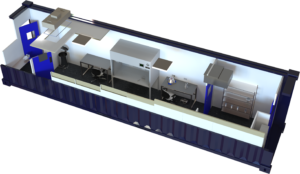

HVAC & Filtration: GT Air Pro

Full function upflow CRAC unit providing temperature and humidity control, utilising direct expansion (DX) to provide cooling and dehumidifying with internal steam boiler for humidifying. AHU ducted to plenum in the ceiling void to provide air distribution to Fan Filter Units (FFUs), exhaust air at low level via grilles into wall plenum, returning back to AHU in the plant room. Condenser housed externally and piped to internal unit. DOWNLOAD DATA SHEET

HVAC & Filtration: GT Air Pro

Full function upflow CRAC unit providing temperature and humidity control, utilising direct expansion (DX) to provide cooling and dehumidifying with internal steam boiler for humidifying. AHU ducted to plenum in the ceiling void to provide air distribution to Fan Filter Units (FFUs), exhaust air at low level via grilles into wall plenum, returning back to AHU in the plant room. Condenser housed externally and piped to internal unit. DOWNLOAD DATA SHEET

-

Environmental Monitoring System: GT Scan Max

In-room LED displays illustrating pressure, temperature and humidity, feeding back to centralised computer screen with GT Scan Max EMS software for alarms and data storage. Alarms are also provided via text, email or phone call as well as in-room beacons. DOWNLOAD DATA SHEET

Environmental Monitoring System: GT Scan Max

In-room LED displays illustrating pressure, temperature and humidity, feeding back to centralised computer screen with GT Scan Max EMS software for alarms and data storage. Alarms are also provided via text, email or phone call as well as in-room beacons. DOWNLOAD DATA SHEET

-

Controls & BMS

All cleanroom plant is controlled with a centralised Graphical User Interface (GUI) via a touchscreen display panel housed in the change area. This receives a signal from the AHU, FFUs, lighting, door interlocks and provides control functionality as well as centralised data that can be back to the main building BMS.

Controls & BMS

All cleanroom plant is controlled with a centralised Graphical User Interface (GUI) via a touchscreen display panel housed in the change area. This receives a signal from the AHU, FFUs, lighting, door interlocks and provides control functionality as well as centralised data that can be back to the main building BMS.

-

Furniture

Standard units include: workbenches, stepover benches, cabinets, racking and dispensers manufactured from grade 304 stainless steel frames and Trespa TopLab work surfaces. Full fit-out available. To view the range CLICK HERE

Furniture

Standard units include: workbenches, stepover benches, cabinets, racking and dispensers manufactured from grade 304 stainless steel frames and Trespa TopLab work surfaces. Full fit-out available. To view the range CLICK HERE

-

Equipment

Standard units do not incorporate equipment. However, full fit-out available. To view the range CLICK HERE

Equipment

Standard units do not incorporate equipment. However, full fit-out available. To view the range CLICK HERE

Guardtech Group Make an Enquiry

Got a question for the CleanCube team? Not sure exactly which solution suits the needs of your application? Click the button below to contact the team now for a rapid response to your enquiry.

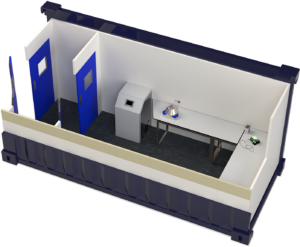

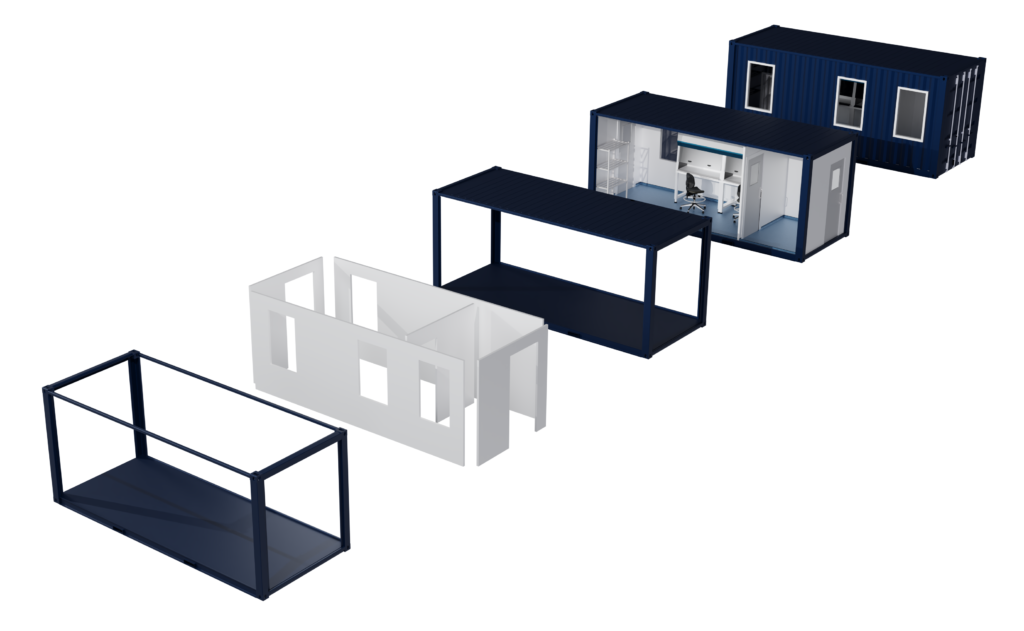

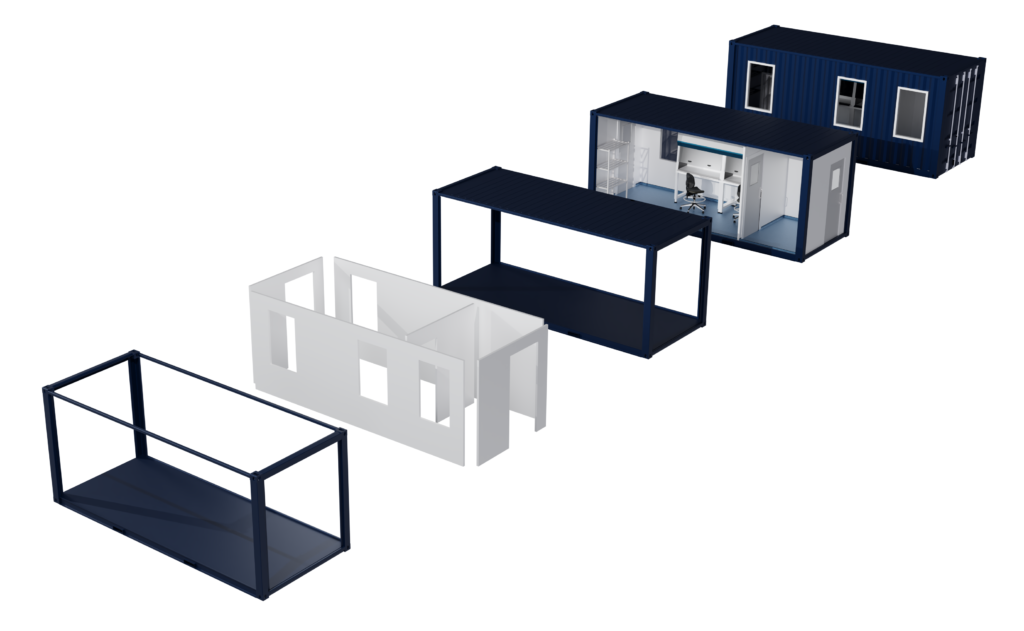

Structural THE MAIN ELEMENTS THAT MAKE UP YOUR CLEANCUBE

Here we consider the various structural components that make up your perfect portable controlled environment – from walls, doors and flooring to ceiling and glazing.

Mechanical & Electrical Your Cleancube’s Key M&E Components

Here we explore the different mechanical & electrical components that you can choose to customise the CleanCube Mobile Cleanroom to best suit your requirements – from filtration and HVAC to power management and environmental monitoring. Pick the parts that work for you.

Furniture & Equipment Fit Out Your Portable Unit In Style

Here we explore the different mechanical & electrical components that you can choose to customise the CleanCube to best suit your requirements – from filtration and HVAC to power management and environmental monitoring.

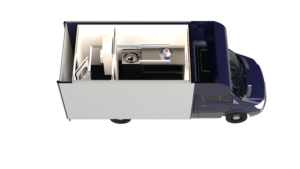

Configurator Build Your Own Cleancube

Tailor your perfect portable controlled environment solution with our CleanCube configurator tool. Modify the elements your CleanCube needs to meet the specific requirements of your application – from classification, temperature and humidity controls to the type of doors or LUX level you want.

We’ve streamlined the process so you can quickly and efficiently order the CleanCube Mobile Cleanroom you need to take your operations to the next level.