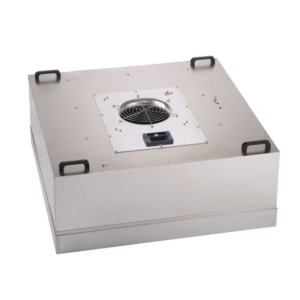

1 Filtration

For ISO 14644 compliant environments Fan Filter Units (FFU) with H14 HEPA filters and G4 pre-filters provide 1,000m³/hour of filtered air. HEPA filtration can also be placed on the exhaust to provide BSL-3 compliance.

For ceiling heights of 2.1m slimline FFUs are installed in the ceiling to provide vertical laminar flow. For ceiling heights of between 2.1m and 2.5m cleanrooms are horizontal flow.

Download Data Sheet

GT Flow Max is a new generation energy-saving Fan Filter Unit with superior performance and reduced power consumption by more than 50% – featuring Roomside Filter Change as standard and a gel seal.

GT Flow Pro is a robust, reliable Fan Filter Unit (FFU) with an efficient AC motor and H14 HEPA filters, which helps to deliver on low energy consumption. This FFU implements a gel seal.

GT Flow Plus is Guardtech’s mid-level Fan Filter Unit (FFU) – featuring an efficient AC motor which helps to deliver on low energy consumption, this FFU implements a gasket seal.

GT Flow Lite is Guardtech’s entry-level fan filter unit – it’s the perfect solution for creating cleanrooms with vertical laminar flow. These are typically installed in false ceilings with proper aluminium profiles.

This product range does not currently include a Fire Rated solution. Please consult a Guardtech rep for more information on your fire safety options.

2 HVAC

Typically, CleanCubes apply temperature control via a VRF (variable refrigerant flow) split system serving a plenum for cleanrooms or wall-mounted recirculating units for labs.

Humidity control is also provided via upflow units or separate desiccant wheels. External condensers can be contained in attached plant rooms or mounted on the CleanCube exterior.

Download Data Sheet

Guardtech’s elite-level air conditioning solution – these high-performance Air Handling Units (AHUs) provide optimum temperature and humidity conditions for a diverse range of applications.

Guardtech’s upper mid-level air conditioning solution – a high-specification upflow unit that offers precision temperature and humidity control to ensure optimum conditions in your cleanroom.

Guardtech’s lower mid-level air conditioning solution – a ducted system that uses a powerful fan coil unit to deliver the ideal temperature and humidity conditions for your cleanroom.

Guardtech’s entry-level air conditioning solution – a wall-mounted cassette (for CNC/laboratories) which can be placed in the CleanCube plenum for cleanrooms.

This product range does not currently include a GT Fire solution. Please contact the team to discuss your options.

3 Environmental Monitoring

Guardtech provide fully integrated Environmental Monitoring Systems that can also be 21CFR Part 11 compliant.

With a range of high-performance multifunction sensors, temperature, humidity and pressure can all be monitored in real time and recorded for an audit trail.

Fully flush or semi flush LED displays give in-room feedback. We have a wide variety of options available.

Download Data Sheet

GT Scan Max is our elite-level EMS – a 21CFR Part 11 compliant system combining state-of-the-art software and hardware to provide accurate readings for temperature, humidity, differential pressure and more.

GT Scan Pro is a flush-mounted multifunction pressure transmitter that can display up to three critical atmospheric parameters, utilising the reliable and highly sophisticated ONCALL-FINESTRA EMS system software.

Wall-mounted transmitter with user-friendly LED display in robust, attractive plastic housing. These multifunction sensors feature interchangeable probes and can display and measure parameters simultaneously.

Guardtech’s entry-level environmental monitoring system – a versatile analogue Magnehelic differential pressure gauge that indicates positive, negative or differential, accurate to within 1%.

This product range does not currently include a Fire Rated solution. Please consult a Guardtech rep for more information on your fire safety options.

4 Power Management

All models require a power connection from an external source.

The rating of this will depend on the power demand of each module.

UPS (uninterruptible power supply) battery back-up can also be provided and a changeover switch can be installed to alternate between a mains and generator supply.

5 Control Panel

15.7” touchscreen HMI+PLC provides a full control and monitoring system for the CleanCube.

The Environmental Monitoring System feeds back to give real-time data on temperature, humidity and pressure.

Fan speeds and HVAC systems can also be controlled as well as other compatible equipment.

6 Fire Alarm

In-room smoke detectors and audible and visual alarm beacons can be installed and linked back to a centralised fire alarm panel.

This can be connected back to the main facility fire panel board if required.

7 Gas Services

Compressed air and other specialist gasses such as N2 and CO2 can be installed, with pipework in stainless 316 or Transair and connection to dedicated compressors, generators or cylinders.

8 Compressed Air & Nitrogen

Compressed air and nitrogen via compressors and generators housed directly within the cleanroom or lab – or in an enclosed plantroom.

Pipework, point of use fittings, regulators and hook-up connections can also be put in place.

Download Data Sheet

9 Extraction

Chemicals, airborne particulate and heat can all be extracted to a localised filtration unit for scrubbing.

Safe change modules can also be placed on the exhaust system to mitigate the risk of cross-contamination.

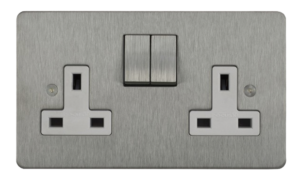

10 13-Amp Sockets

All CleanCube models can include stainless steel or white plastic 13-amp sockets mounted flush.

CAT6 network sockets and 16-amp or 32-amp three-phase sockets are also available in the range.

11 Lighting

Powder-coated steel light units, flush mounted into the ceiling panels with drop-down hinged diffuser.

Also available as surface-mounted aluminium LED batten luminaires for laboratories.

Activation by switch or PIR (passive infrared) sensor. Lights can be UV filtered for photo sensitive processes.

Download Data Sheet

GT Lux Max is Guardtech’s elite-level light solution – a top-end luminaire offering optimum control via a Digital Addressable Lighting Interface (DALI) system or SmartScan lighting management system.

GT Lux Pro is a high-quality and robust LED luminaire with a highly efficient light source – the unit opens from the top, meaning that maintenance is easy and decontamination risks are reduced.

GT Lux Plus is a highly efficient LED that has been engineered to be mounted in modular and suspended ceilings – the luminary body is made from steel sheet and powder coated in white.

GT Lux Lite is Guardtech’s entry-level light solution – an LED ceiling tile lighting panel that delivers on performance while allowing clients to save their budget for other critical areas of the project.

GT Lux Fire is Guardtech’s Fire Rated light solution – a high quality LED luminaire with a corrosion resistant, zinc-coated steel body that meets the requirements of Zone 1 hazardous areas.

12 Containment

For cleanrooms, Guardtech install sockets and services flush to the panel system with containment embedded within the panel core.

For laboratories, three-compartment PVC trunking is used for flexibility of socket positioning and cost effectiveness.

13 Network

Guardtech can provide Cat6 network ports – either flush or in containment – to ensure your CleanCube is fully equipped for all your data needs.

Cat6 cables have stricter performance specifications and significantly higher data transfer speeds at greater distances than Cat5/5e cables.

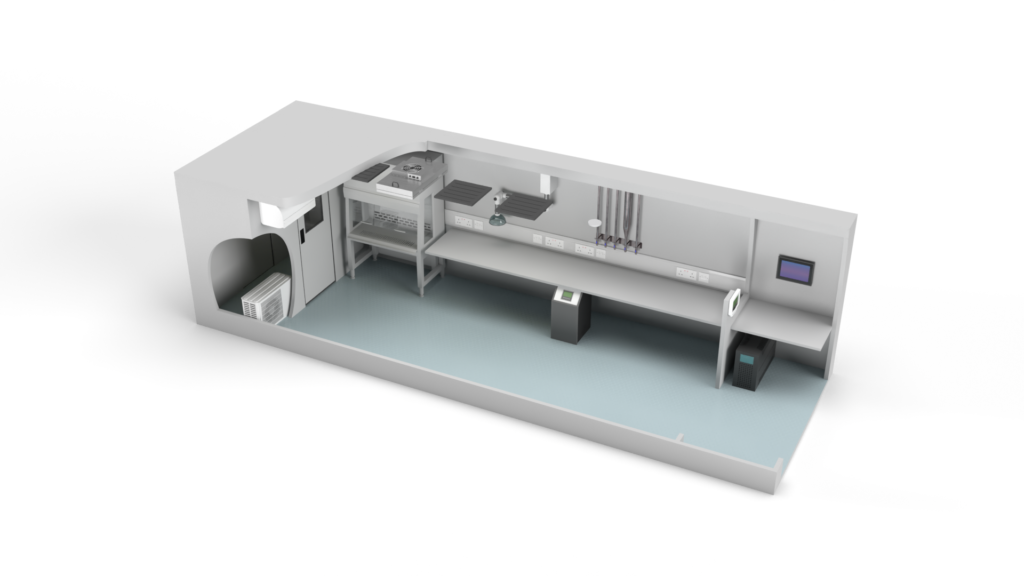

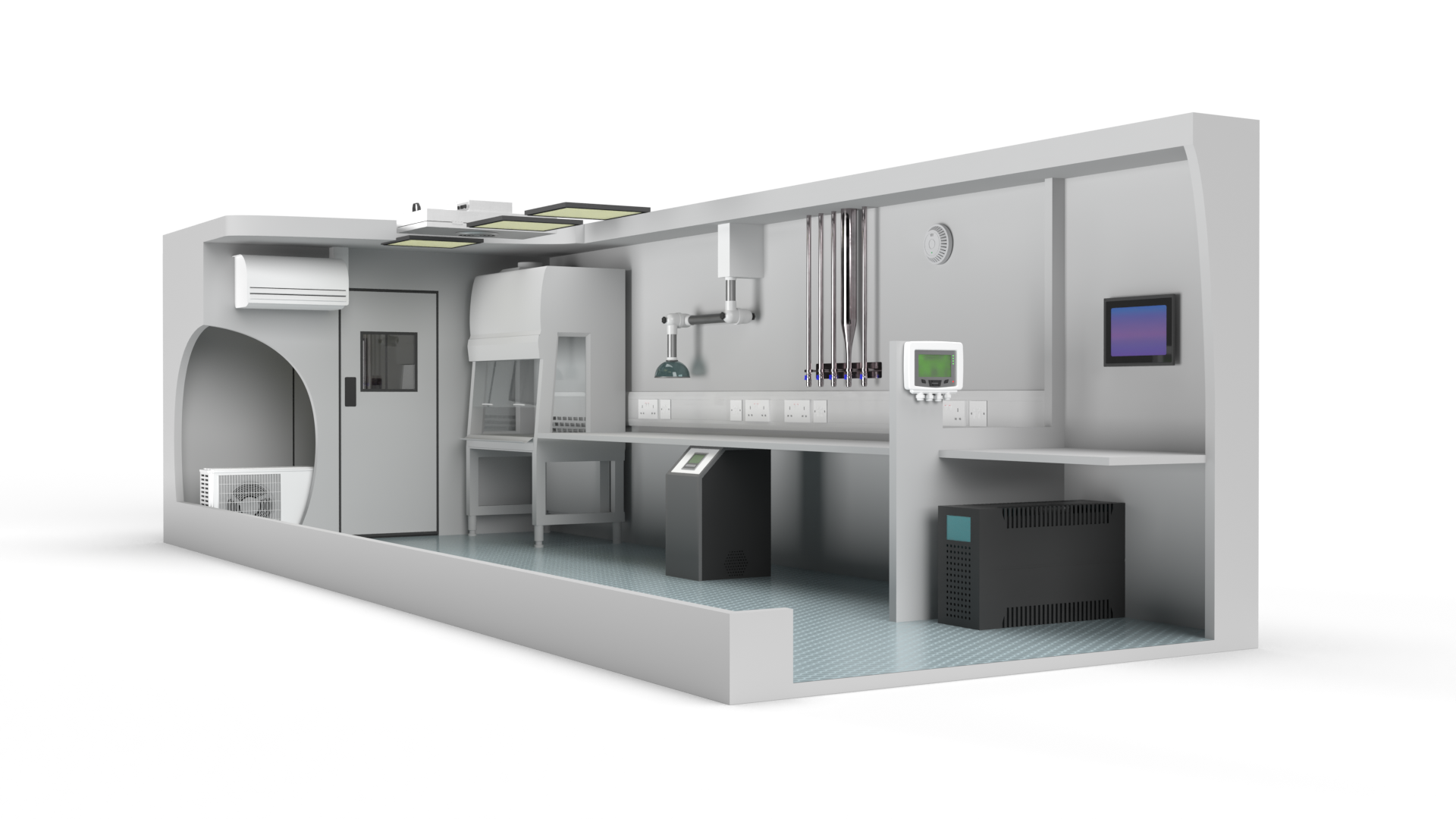

Structural THE MAIN ELEMENTS THAT MAKE UP YOUR CLEANCUBE

Here we consider the various structural components that make up your perfect portable controlled environment – from walls, doors and flooring to ceiling and glazing.

Furniture & Equipment Fit Out Your Portable Unit In Style

Guardtech offer a wide range of furniture & equipment solutions to help you get the most out of your CleanCube. From Trespa workbenches, cleanroom-grade chairs and shelving right through to biosafety cabinets, laminar flow units and transfer hatches.

Configurator Build Your Own Cleancube

Tailor your perfect portable controlled environment solution with our CleanCube configurator tool. Modify the elements your CleanCube needs to meet the specific requirements of your application – from classification, temperature and humidity controls to the type of doors or LUX level you want.

We’ve streamlined the process so you can quickly and efficiently order the CleanCube Mobile Cleanroom you need to take your operations to the next level.

Guardtech Group Make an Enquiry

Got a question for the CleanCube team? Not sure exactly which solution suits the needs of your application? Click the button below to contact the team now for a rapid response to your enquiry.