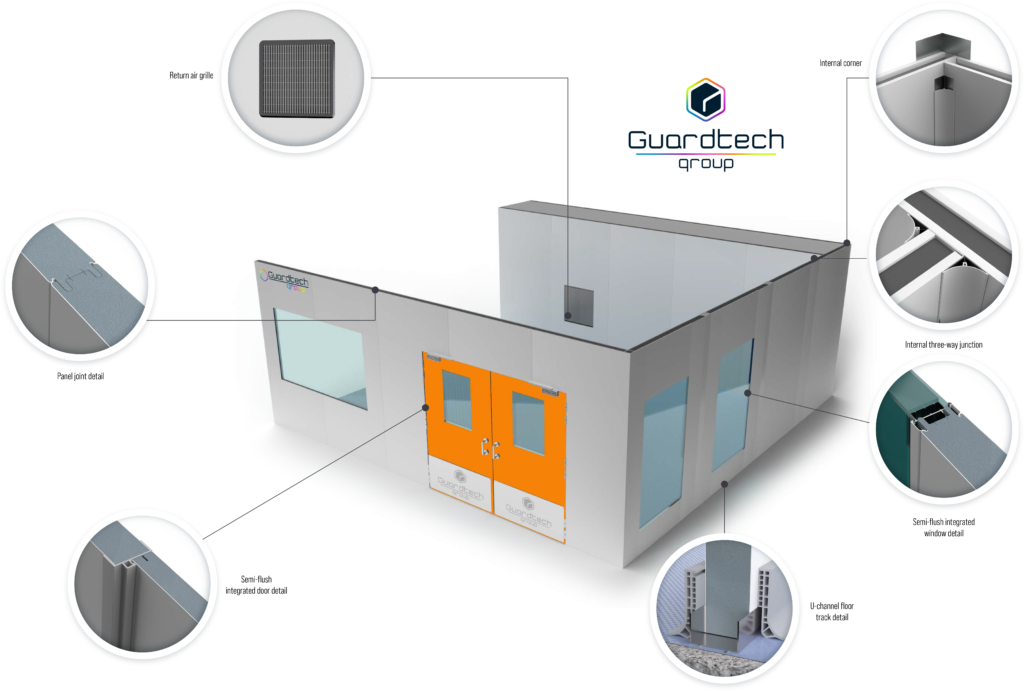

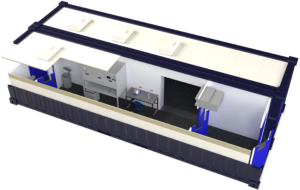

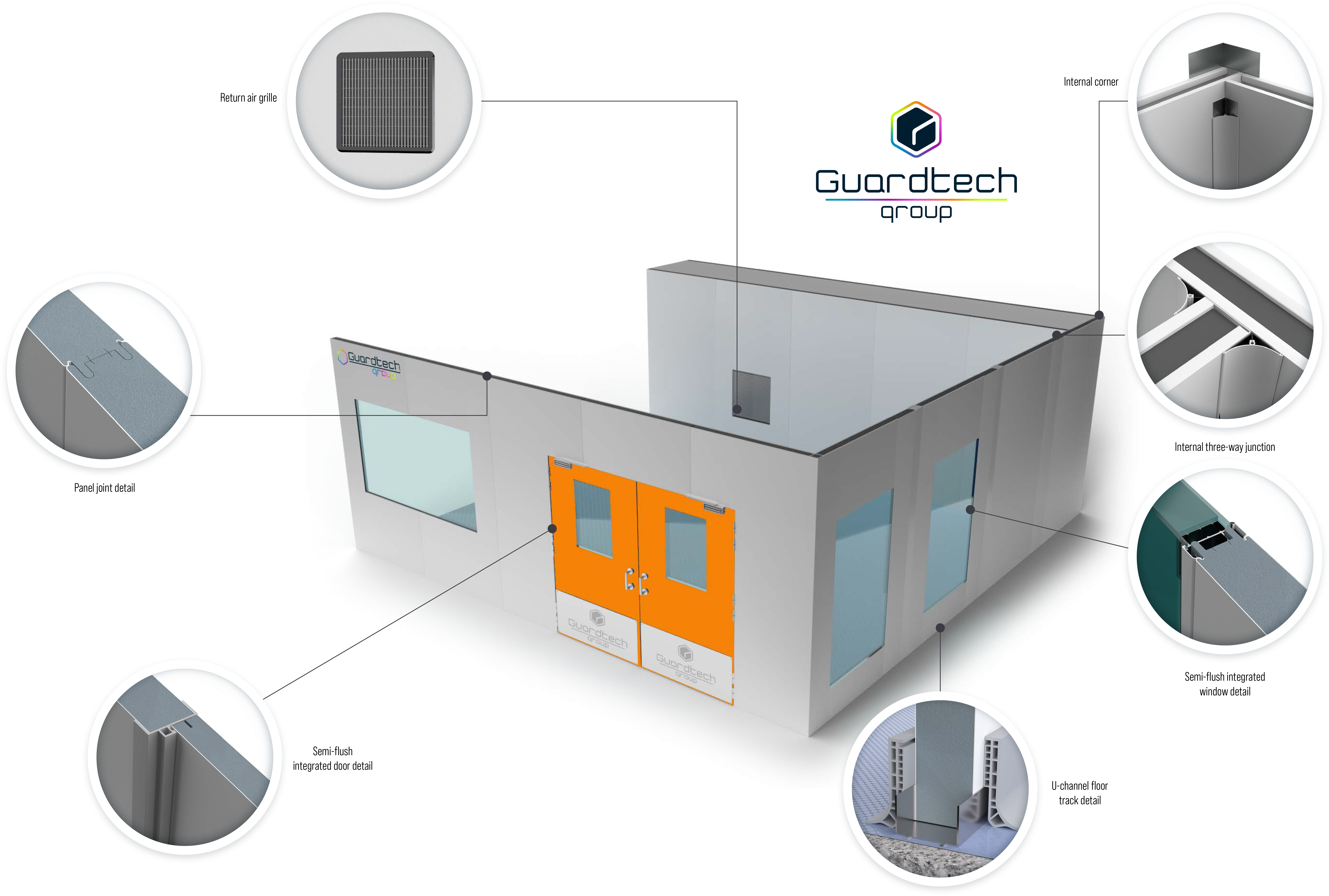

THE CNC Specification is designed to provide a cost-effective balance of componentry that will best suit an unclassified controlled environment.

CNC utilises materials that are specified for lower-grade cleanroom builds whilst downgrading some of the mechanical & electrical interfaces typically excluded from cleanrooms, thus providing a high-grade laboratory finish whilst utilising off-the-shelf components and plant.

Utilising a composite panel system for the main structural elements, such as walls and ceilings, and ensuring that supporting components including doors, glazing, flooring, lighting and accessories are manufactured from laboratory quality materials, whilst also considering furniture & equipment layouts to best utilise space.

The CleanCube CNC Specification also logically incorporates and conceals all utilities by utilising the channel behind the wall panels, eliminating surface-mounted pipework, cabling and service conduits.

CNC SPECIFICATION TECHNICAL DATA

Components

-

Classifications Available

Controlled Not Classified

Classifications Available

Controlled Not Classified

-

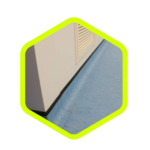

Walls: GT Shell Plus

CLEANsafe insulated panels incorporating a panel joint that achieves excellent thermal performance and can accommodate vapour and hygiene safe seals. GT Shell Plus panels achieve low air leakage and resist moisture ingress and any risk of toxic mould and bacterial growth thanks to intelligent QuadCore insulation technology, with superior fire protection and enhanced environmental credentials via lifetime performance and high efficiency. DOWNLOAD DATA SHEET

Walls: GT Shell Plus

CLEANsafe insulated panels incorporating a panel joint that achieves excellent thermal performance and can accommodate vapour and hygiene safe seals. GT Shell Plus panels achieve low air leakage and resist moisture ingress and any risk of toxic mould and bacterial growth thanks to intelligent QuadCore insulation technology, with superior fire protection and enhanced environmental credentials via lifetime performance and high efficiency. DOWNLOAD DATA SHEET

-

Doors: GT Access Lite

Powder-coated steel door with a standard anodised aluminium frame, featuring ECOSafe PIR insulation core and a clear opening width of 1100mm (single) or 2200mm (double). 40mm door leaf thickness, available in XL forté and Spectrum external coatings and CLEANsafe internal coatings, including vision panels and aluminium kickplates as standard. DOWNLOAD DATA SHEET

Doors: GT Access Lite

Powder-coated steel door with a standard anodised aluminium frame, featuring ECOSafe PIR insulation core and a clear opening width of 1100mm (single) or 2200mm (double). 40mm door leaf thickness, available in XL forté and Spectrum external coatings and CLEANsafe internal coatings, including vision panels and aluminium kickplates as standard. DOWNLOAD DATA SHEET

-

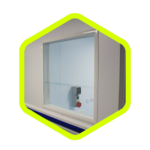

Glazing: GT Vision Plus

Fully flush mounted glazed units consisting of aluminium frame and two panes of 6mm thick laminated glass, glued and silicone sealed on both sides to the frame. Frame features moisture-free silica-gel granules. Glazing panels slot into the holistic integrated envelope solution via extruded aluminium interface connection profiles.

Glazing: GT Vision Plus

Fully flush mounted glazed units consisting of aluminium frame and two panes of 6mm thick laminated glass, glued and silicone sealed on both sides to the frame. Frame features moisture-free silica-gel granules. Glazing panels slot into the holistic integrated envelope solution via extruded aluminium interface connection profiles.

-

Ceiling: GT Lid Pro

A 45mm radius coving is applied to bridge the 90-degree join between wall and ceiling panel. Ceiling panels use the same ultra-airtight integrated envelope system, utilising extruded aluminium interface connection profiles to ensure a fully flush detail – finished with silicone seal. Pre-formed corner panels provide a flush finished external corner detail. DOWNLOAD DATA SHEET

Ceiling: GT Lid Pro

A 45mm radius coving is applied to bridge the 90-degree join between wall and ceiling panel. Ceiling panels use the same ultra-airtight integrated envelope system, utilising extruded aluminium interface connection profiles to ensure a fully flush detail – finished with silicone seal. Pre-formed corner panels provide a flush finished external corner detail. DOWNLOAD DATA SHEET

-

Flooring: GT Deck Lite

Vinyl, hot-welded and coved 100mm from floor level, connection to wall via overlay onto the panel and finished with a rubber capping strip and silicone seal. DOWNLOAD DATA SHEET

Flooring: GT Deck Lite

Vinyl, hot-welded and coved 100mm from floor level, connection to wall via overlay onto the panel and finished with a rubber capping strip and silicone seal. DOWNLOAD DATA SHEET

-

Utilities Integration

Most utilities will be terminated with wall mounted sockets/outlets with wiring, pipework and containment concealed behind the wall panel within the return air plenum. All penetrations will be silicone sealed, small power and data sockets will be flush mounted.

Utilities Integration

Most utilities will be terminated with wall mounted sockets/outlets with wiring, pipework and containment concealed behind the wall panel within the return air plenum. All penetrations will be silicone sealed, small power and data sockets will be flush mounted.

-

Lighting: GT Lux Plus

Recessed LED, 4k colour temperature, 4,400 lumens per light fitting providing 500 lux at bench level. Roomside access diffuser for clean LED change. PIR motion sensor activated. DOWNLOAD DATA SHEET

Lighting: GT Lux Plus

Recessed LED, 4k colour temperature, 4,400 lumens per light fitting providing 500 lux at bench level. Roomside access diffuser for clean LED change. PIR motion sensor activated. DOWNLOAD DATA SHEET

-

HVAC & Filtration: GT Air Lite

Wall-mounted cassettes providing air conditioning via recirculated air matched with external condensers sized to overcome room heat gains and provide stable temperature control. DOWNLOAD DATA SHEET

HVAC & Filtration: GT Air Lite

Wall-mounted cassettes providing air conditioning via recirculated air matched with external condensers sized to overcome room heat gains and provide stable temperature control. DOWNLOAD DATA SHEET

-

Environmental Monitoring System: GT Scan Plus

In-room LED displays illustrating pressure, temperature and humidity, feeding back to centralised computer screen with GT Scan Plus EMS software for alarms and data storage. DOWNLOAD DATA SHEET

Environmental Monitoring System: GT Scan Plus

In-room LED displays illustrating pressure, temperature and humidity, feeding back to centralised computer screen with GT Scan Plus EMS software for alarms and data storage. DOWNLOAD DATA SHEET

-

Controls & BMS

Lights are controlled via PIR motion detection sensor, air conditioning controlled via wall-mounted digital display.

Controls & BMS

Lights are controlled via PIR motion detection sensor, air conditioning controlled via wall-mounted digital display.

-

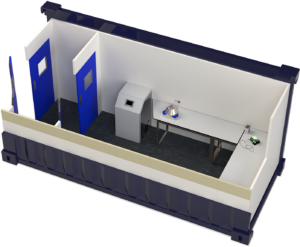

Furniture

Standard units include: workbenches, stepover benches, cabinets, racking and dispensers manufactured from grade 304 stainless steel frames and Trespa TopLab work surfaces. Full fit-out available. To view the range CLICK HERE

Furniture

Standard units include: workbenches, stepover benches, cabinets, racking and dispensers manufactured from grade 304 stainless steel frames and Trespa TopLab work surfaces. Full fit-out available. To view the range CLICK HERE

-

Equipment

Standard units do not incorporate equipment. However, full fit-out available. To view the range CLICK HERE

Equipment

Standard units do not incorporate equipment. However, full fit-out available. To view the range CLICK HERE

Guardtech Group Make an Enquiry

Got a question for the CleanCube team? Not sure exactly which solution suits the needs of your application? Click the button below to contact the team now for a rapid response to your enquiry.

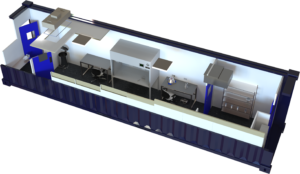

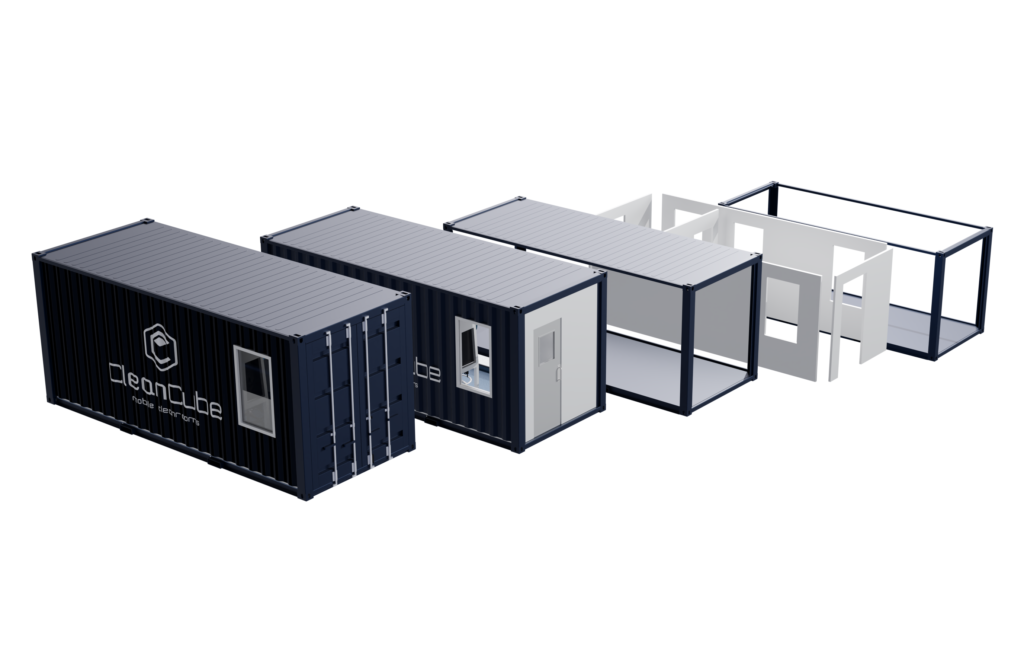

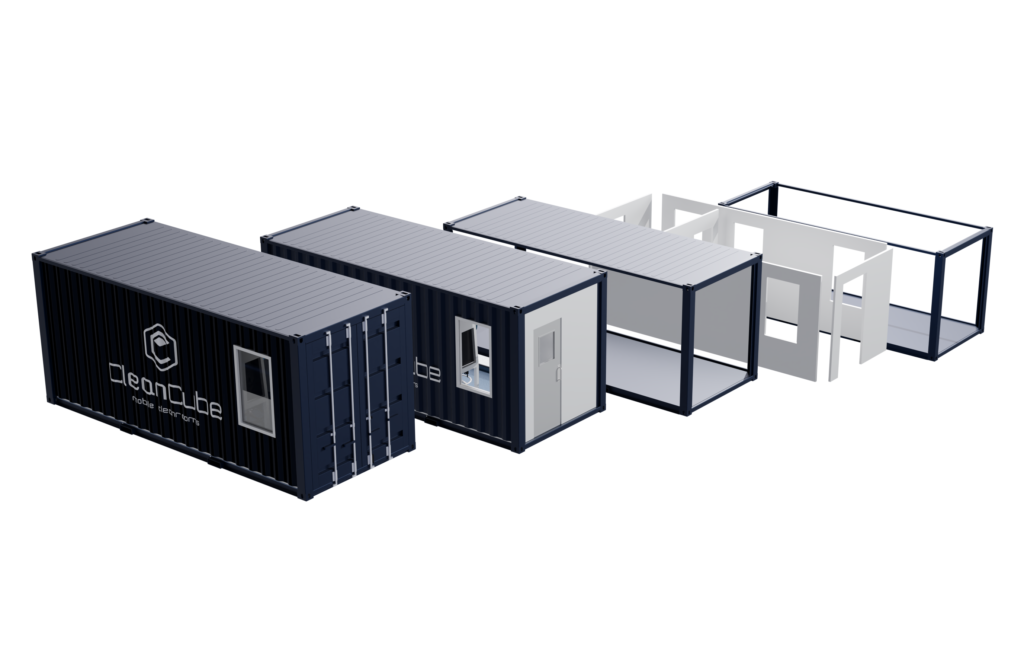

Structural THE MAIN ELEMENTS THAT MAKE UP YOUR CLEANCUBE

Here we consider the various structural components that make up your perfect portable controlled environment – from walls, doors and flooring to ceiling and glazing.

Mechanical & Electrical Your Cleancube’s Key M&E Components

Here we explore the different mechanical & electrical components that you can choose to customise the CleanCube to best suit your requirements – from filtration and HVAC to power management and environmental monitoring.

Furniture & Equipment Fit Out Your Portable Unit In Style

Guardtech offer a wide range of furniture & equipment solutions to help you get the most out of your CleanCube. From Trespa workbenches, cleanroom-grade chairs and shelving right through to biosafety cabinets, laminar flow units and transfer hatches.

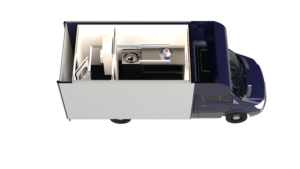

Configurator Build Your Own Cleancube

Tailor your perfect portable controlled environment solution with our CleanCube configurator tool. Modify the elements your CleanCube needs to meet the specific requirements of your application – from classification, temperature and humidity controls to the type of doors or LUX level you want.

We’ve streamlined the process so you can quickly and efficiently order the CleanCube Mobile Cleanroom you need to take your operations to the next level.